Fitting SMITHS chronometric cables

When fitting you must:

- Check the drive end of the outer cable is properly fitted, and the inner cable end is firmly home into the drive end socket.

- Then check that the amount of inner cable protruding at the instrument end is less in length than the depth of the drive socket on the instrument. There must be free space, and the inner is not tight.

- Also check to see if a small piece of cable has broken off and jammed in the drive end socket at the drive end.

The above applies to all chronometric and magnetic instruments and is particularly applicable to motorcycles where cheap imported cables are used.

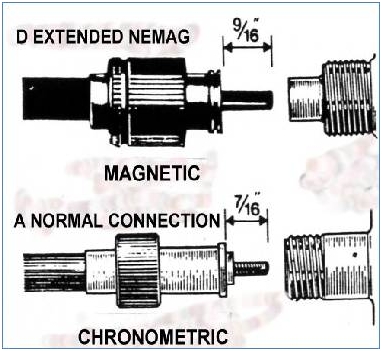

Always check carefully that the inner cable fully enters the instrument without any force being required. It is best to fit the cable to the speedometer gearbox or tacho drive first. The amount of inner cable and particular instrument will accept is somewhat variable but any chronometric should accept at least 3/8 inch and any magnetic 1/2 inch measuring from the end of the alloy ferrule on the inner cable.Cable ends

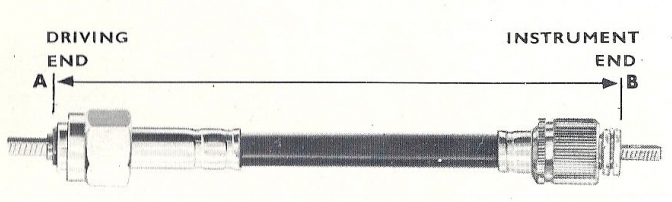

Speedo Cable dimensions

The nominal length of a flexible drive is measured between 'A' and 'B', on the outside of the ferrules.

Bowden cable (Choke, clutch, brake etc) dimensions

Are measured by denoting the OVERALL length inside the nipples.

Handlebar lever cable adjusters (Choke, clutch, brake etc)

A standard cable will not fit handle bar levers with adjusters built in unless it is a later version such as Commandos where this was a standard configuration. Inner cables must be approx 40mm longer for adjusters but the variation will depend on the brand of adjuster.